capsule filling machine working principle

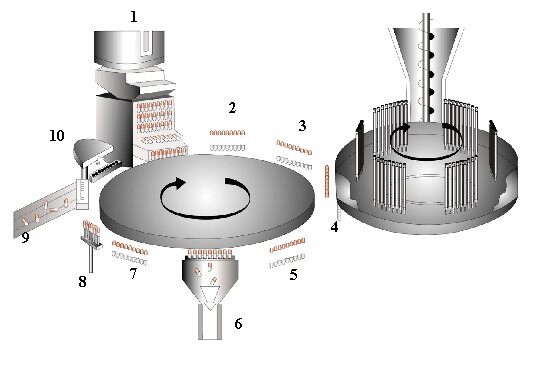

The powder here is compacted with the help of a tamping punch. The meter disk rotates once after taming to transfer the dust to the next destroyer and the dust on the meter disk automatically fills the holes in the meter disk.

Working Principle of A Capsule Filling Machine.

. Every machine has its own working method. These personal capsule filler machines allow people to fill their capsules with the necessary medication. But how does a process like this wor.

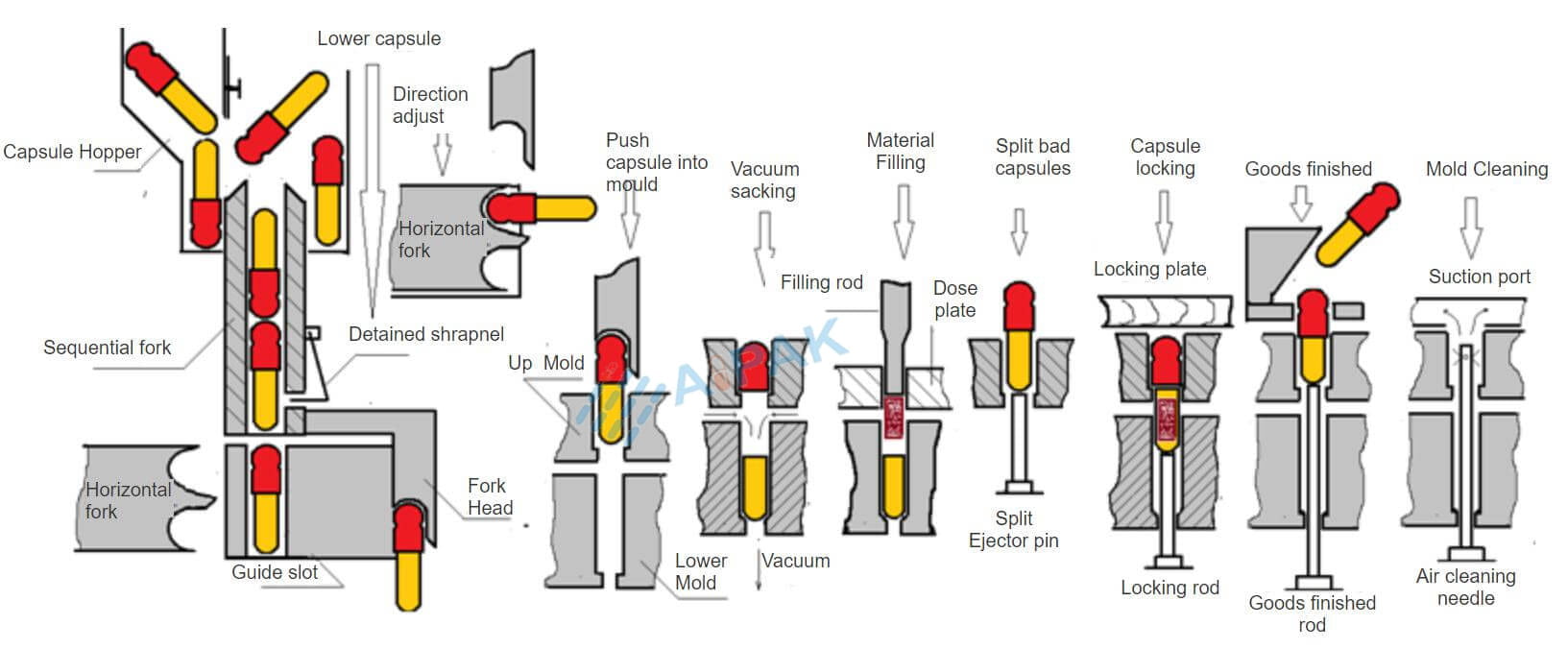

Specifically we provide high-throughput topical formulation screening and. This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight. The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork one by one.

It can be done by a number of different methods. Rearrange the caps and bodies. Over 5000 happy customers.

A dosator machine with two segments powder and capsule sections. Regardless of the type and model of your auto or semi-automatic capsule filling machine a vacuum system is vital. The liquid filling machine works when the pressure is high.

This can be done either manually or by means of an automated capsule filling machine. Liquid Filling Machine Its Principles. Cover the filled lower mold with the upper mold and move them to the locking station ensuring that the thimble is inserted into the hole of the mold.

The machine that can greatly improve production efficiency and reduce labor costs. Available For Sizes 0 00 000 - Order A Single Tray Or A Case Of 13 To Receive Discount. By creating the FEC40 Fette Compacting has proven its innovative capabilities regard to the industrial capsule filling.

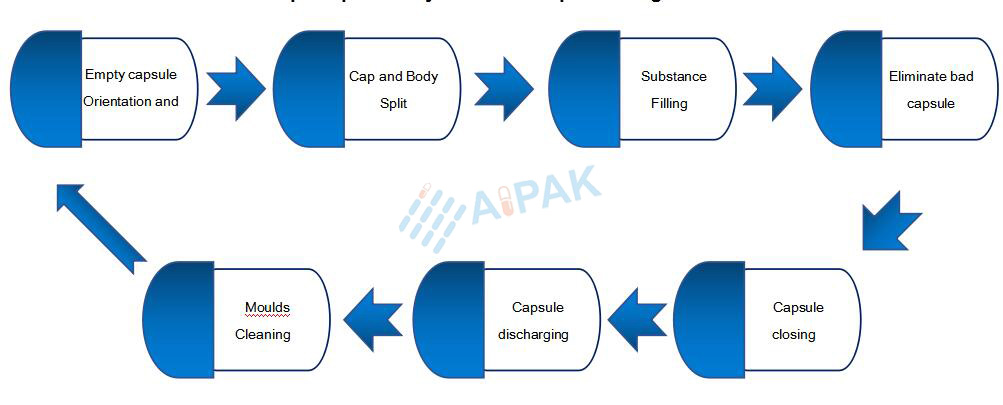

Now with the continuous improvement of the filling technology the automatic capsule filling machine is becoming higher and higher automated and the filling speed is getting faster and faster from tens of thousands to hundreds of thousands. Ad Compact Filling Tray To Manually Fill Your Empty Capsules With Supplement Ingredients. Division of capsule caps from their bodies.

Rectification orientation of the bad gelatin capsules. The powders are transferred from one tamping punch to next to achieve a smooth finish. Rent buy or lease Filling Capsule Equipment Machines.

1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push rod through the capsule tank. The Working Principle of SaintyCo Dosator Capsule Filling Machine. Hand Operated capsule filling machine.

WORKING PRINCIPLE OF VISCOUS LIQUID FILLING MACHINE. Even though the process seems simple and straightforward any failuremalfunction in any of the tamping pins may cause serious loss high rate of capsule rejection. Filling up the capsule body with pharmaceutical ingredients.

The Working Principle Of Automatic Capsule Filling Machine. First the vacuum loader connects the capsule loading device to the capsule hopper and material loading port to the material hopper. Then turn over the locking cover and eject the capsule by pressing the foot pedal or locking button.

The system is such that the powder bed is on one side while the empty capsule body is on the opposite side. And after solidification the powder fills the capsule body. Ejection of filled capsules.

Ad Browse through 75 Used New Filler Powder Capsule Machines. The body of the capsule is transferred to the filling station where the active ingredients are filled in the capsule. The capsule before sent for packing needs to be properly processed and filled with the help of a capsule Filling machine.

AF 90 T AUTOMATIC CAPSULE FILLING MACHINE. In short the working principle of a tamping type capsule filler involves a number of stages whose consistency and performance should be monitored. The positioning of colourless translucent capsules in the capsule filling tray.

Automatic capsule filling machine is a fully automatic capsule filling machine with which capsule separation filling and locking can be done automatically. What is the working principal of capsule filling machine. First with the help of this component the product that is due for packaging is loaded with viscous liquid.

The capsules are rectified caps and bodies are separated active pharmaceutical ingredients API is filled wasted capsules are rejected capsules are. Just as the name suggests this type of capsule filling machine is manually operated. Empty shell will be loaded in capsule sorter elevator from there capsule will be filled at empty capsule loader body cap segment will be separated through Maxine.

A dosator machine may have two segments. Working Principles of Various Filling Machines 1. Once the liquid matter is filled the corking unit is individually responsible for placing caps and lids on the packed vessels.

Personal capsule filling machines is for small scale production and utilization. Second the vacuum system separates the empty capsule to avoid damage. Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process.

Press the filling button ON to fill the capsule. It ha a lever and a calm handle which allow you to control the operation of the machine by using hands. In the working principle of the bottle filling machine there is a cork accumulation tray.

Separation of capsule caps from bodies. Contact Us Send Inquiry. In stock ready to ship.

Automatic capsule filling machine working principle. Working Principle of Capsule Filling Machine. - Thursday June 6 2019.

Dosing of fill materialformulation filling the bodies. Rejoining of caps and bodies. Capsule filling machines use a hammer to compact the powder.

Manual gelatin capsule filling machine is ideal for small-scale production. The capsule filling machine works in a step-by-step process that is as mentioned below. When the fork is sent down six capsules are delivered at a.

In this station the upper and lower parts of the capsule body are separated by vacuum suction. Senieer FBM Series fluid bed processor working principle offers the possibility to dry granulate or coat particles in a single machine. Capsule filling machines should all have the following operating principles in common.

Automatic Capsule Filling Machine Working Principle Ipharmachine Academiaedu is a platform for academics to share research papers. Operating principles of a capsule filling machine. On the other hand professional capsule fillers are used in pharmaceutical industries at large scale production with high efficiency.

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine High Speed Capsule Filler

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

Tamping Pin Type Capsule Filling Machine Working Principle

10 Powerful Benefits Of Saintyco Dosator Capsule Filling Machine Saintytec

Filling Machines Their Working Principles

Automatic Capsule Filling Machine High Speed Capsule Filler

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Capsule Filling Machine The Blueprint Guide Saintyco

Hard Shell Capsule Filling Machines Basicmedical Key

Powder Filling Drug Absorption Pharmacological Sciences

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Automatic Capsule Filling Machine Working Principle Ipharmachine